Table of Contents

I. THE PROBLEM: When Brittle Pipes Threaten a Manufacturer’s Reputation

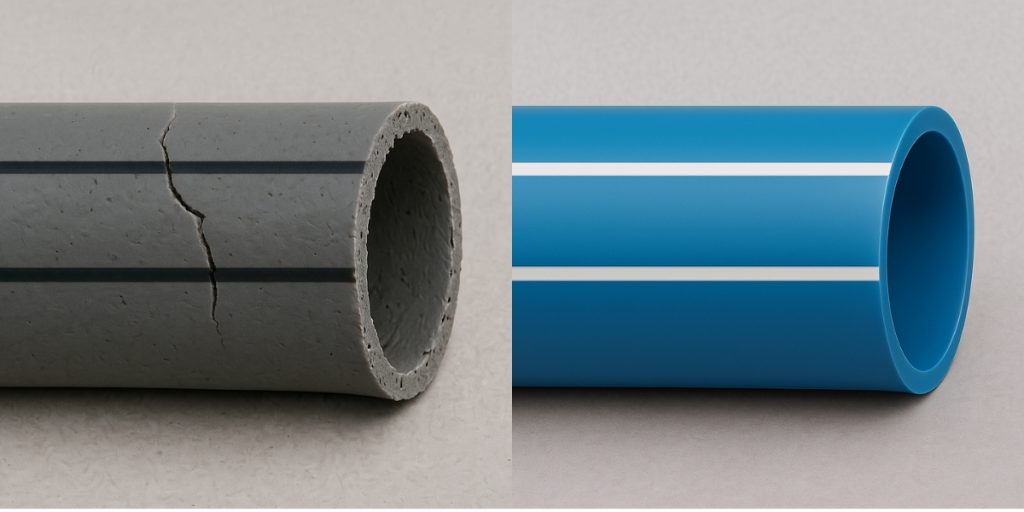

CaCO3 Powder for PVC Pipe Impact Strength became the defining factor in a major technical failure faced by a large PVC pipe manufacturer in Ecuador. Their products were brittle, cracking under pressure, and showing signs of “chalking.”

The core problem: The pipes failed to meet essential mechanical standards for crucial water supply projects. Despite using standard CaCO3 Powder from various suppliers, their formulation was consistently failing.

II. The Hidden Costs of Technical Failure

This was not just a quality issue; it was an escalating crisis of cost and confidence.

- Financial Waste: The scrap rate for failed products was high. Every meter of failed pipe was wasted material, labor, and machine time, directly attacking their goal of Lower production costs.

- Market Trust: Contractors and civil engineers were losing confidence. Their brand reputation was damaged, and they risked losing major contracts to competitors.

- Technical Frustration: Their R&D team was stuck. The root cause was the old CaCO3 Powder filler: its particle size was too fine (D97 > 13µm), which damaged the polymer structure and destroyed the product’s toughness.

They were producing a product they could not trust.

III. THE SOLUTION: A Solution-Oriented Approach to Formulation

The Global Minerals technical team diagnosed the problem rather than just selling a product. The solution was not any powder; it was the right powder.

We proposed our Coated Calcium Carbonate Powder – NHA1, a grade specifically engineered for rigid PVC Pipes and pressure applications.

- The Technical Fix

Particle Size Precision: D50:2±0.3 microns and D97:8±2 microns

High Purity CaCO3 Powder > 98.5

Visual Quality: Whiteness ≥ 98%

Moisture: ≤ 0.2%:

The difference was the precisely controlled particle size (D97: 8 ± 2 microns). This was the key – not too fine (which causes brittleness) and not too coarse (which affects the surface). It was perfectly balanced to maintain polymer toughness.

- The Application Support: We did not just send a sample. We provided technical guidance to their R&D team via video call, helping them find the optimal mixing ratio (25-30% CaCO3 + CPE additive) to guarantee impact durability.

IV. THE TURNING POINT: From Raw Data to Conclusive Proof

The decision point was clear during the 0∘C impact test

The old pipes shattered while the pipes made with NHA1 did not crack or break. This technical validation confirmed the difference in material quality.

| Result Category | Key Improvement | Financial/Efficiency Gain |

| Product Strength | Pipe durability increased by 15% | Increased product reliability and helped secure project contracts |

| Profit & Efficiency | CaCO3 provided a stable base, allowing the client to save 10-12% on total production costs. | Estimated $100,000−$120,000 USD annual savings and 20% reduction in waste |

| Market Growth | Client saw a 10% increase in sales and gained new civil engineering projects. | Proof that technical quality drives financial strength. |

“Our pipes used to be brittle and crack easily. With your CaCO3 Powder, they’ve become stronger, more flexible, and glossier — all while reducing costs.” — Production Director, PVC Pipe Factory, Ecuador

The true strength of your PVC pipe starts with the right CaCO3 Powder solution. Achieve “Sustainability” in the PVC industry is not just about price. It is about passing the impact test, every single time.

Watch Global Minerals Fix Brittle PVC Pipes with High-Purity CaCO3 Powder

Request a technical consultation to optimize your PVC formula here