Table of Contents

I. THE PROBLEM: The High-Cost Quality Trap

In this case study on paint cost optimization, we analyze how a major manufacturer in Bangladesh overcame the high-cost quality trap.

- Quality Issue: Their paint products had poor hiding power and were turning yellow after sun exposure.

- Cost Issue: To fix the quality, they were forced to use more of the single most expensive ingredient in their formula: Titanium Dioxide (TiO₂).

They were trapped. To deliver good quality, they had to accept high, unpredictable costs. This destroyed their profit margins and made them uncompetitive.

II. The Real Risk of Unstable Prices

The real problem was not just the high cost; it was the instability.

Their entire profit model was tied to the unstable global price of TiO₂. A sudden price spike could wipe out their profit for the quarter. They couldn’t create accurate budgets. They couldn’t offer stable, long-term pricing for large projects.

They were stuck in a cycle of “temporary fixes” (like chasing cheaper TiO₂ batches) instead of finding a long-term, stable solution. They didn’t just need a discount but a new, sustainable formula.

III. THE SOLUTION: A New Formula for Paint Cost Optimization

Global Minerals provided a technical diagnosis, not just a product. The old, low-whiteness filler was the root cause.

We proposed a new formula built on our high-performance Uncoated Calcium Carbonate – NH4 grade. This specific CaCO3 Powder was engineered to solve their problem in two ways:

- High Whiteness (≥98%): Our product is naturally bright. It immediately improved the base color, meaning less TiO₂ was needed to achieve a pure white.

- Optimized Particle Size (D97 25 ± 2 μm): This specific size distribution improved the paint’s hiding power (coverage) and provided a smoother surface finish.

We also provided full lab support to help them test and prove the new, optimized formula.

Discover Inside Global Minerals’ QC Lab: How We Ensure CaCO3 Powder Quality

IV. THE RESULT: Sustainable Profit and Proven Quality

The validation was clear and immediate.

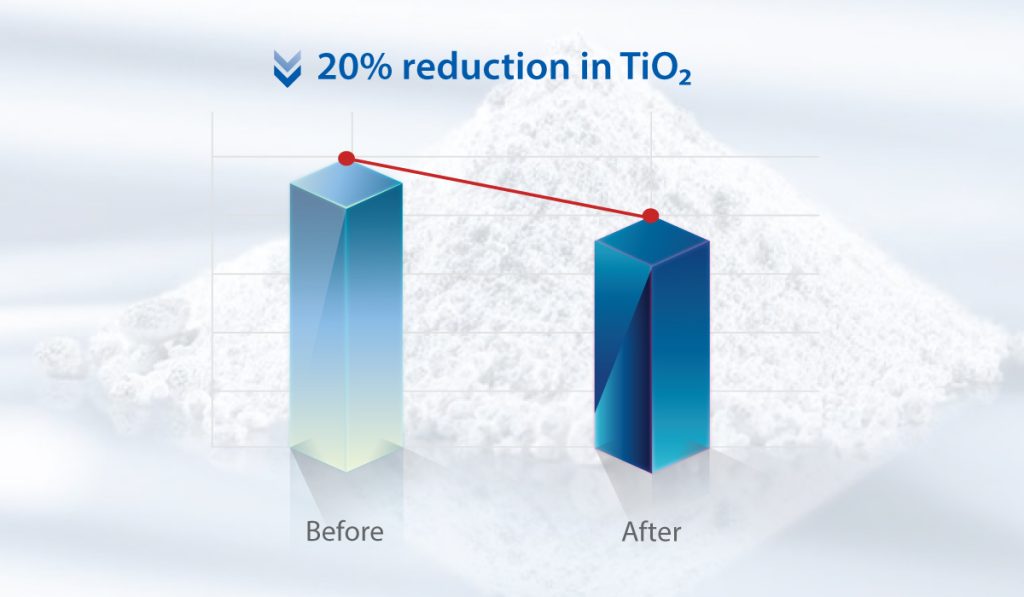

- The Proof: Lab tests confirmed the new formula achieved the same high-quality hiding power, but with a significant reduction in TiO₂.

- The Financial Result: The client reduced TiO₂ consumption by 10-20%. This led to a total formulation saving of 8-12% per ton of paint.

- The Business Result: This is the definition of sustainable profit. It was not a one-time saving. The client is now less dependent on unstable TiO₂ prices. This new formula gives them control over their costs and profits.

- Bonus Result: The improved quality (better coverage, less yellowing) helped them increase sales by 5-12%.

TiO₂ prices will always change. Your formula shouldn’t be a victim.

Ready for paint cost optimization in your own factory? Send us your current formulation for a free audit, and let’s calculate your potential savings today. Contact us now