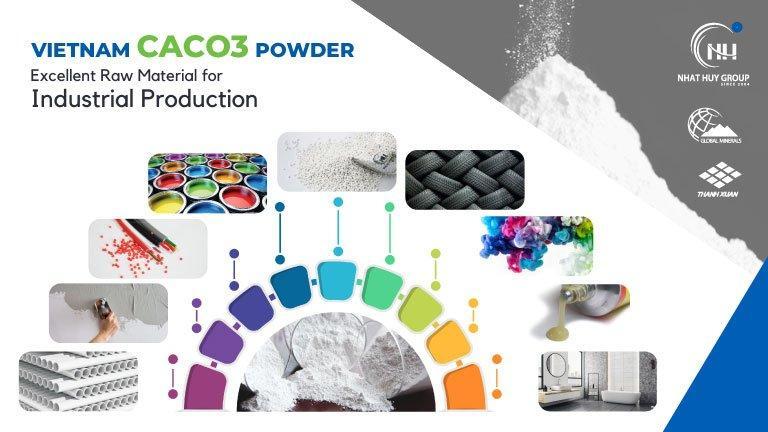

Explore the differences between Coated and Uncoated Calcium Carbonate Powder, which are common raw materials for many industries.

Due to its versatility and cost-effectiveness, Calcium Carbonate (CaCO3) powder is a crucial material in many industries. Global Minerals offers coated and uncoated calcium carbonate powders, each catering to specific industrial needs. Understanding the differences between these two forms can help you choose the right type for your applications.

Formulation Differences Between Coated and Uncoated Calcium Carbonate

Formulation of Coated Calcium Carbonate Powder

Coated calcium carbonate is treated with a surface coating, typically with stearic acid, which enhances its properties.

The coating:

Improves dispersion in organic matrices such as plastics and rubber.

Increases compatibility with the polymers, aiding in processing and final product durability.

Reduces moisture absorption, which is crucial for applications where the dryness of the product is essential.

Formulation of Uncoated Calcium Carbonate Powder

Uncoated calcium carbonate does not have any surface treatment. This form:

Retains the natural properties of calcium carbonate.

It offers higher reactivity, which is beneficial in applications like cement and other building materials requiring quick reaction times.

It is generally more cost-effective due to the absence of additional processing.

Differences Between Applications of Coated and Uncoated Calcium Carbonate

The applications of Coated Calcium Carbonate Powder are not as diverse as those of Uncoated Calcium Carbonate Powder.

Applications of Coated Calcium Carbonate Powder

PVC Pipes and Fittings: Improve Quality and Durability.

PVC Compound: Amplify Performance and Aesthetics.

Filler Masterbatch: Optimize Properties for Better Processing and Quality.

Rubber: Increase Strength and Durability.

Applications of Uncoated Calcium Carbonate Powder

PVC Pipes and Fittings: Improves durability and impact resistance.

PVC Compounds: Enhances flexibility and surface finish.

Filler Masterbatch: Optimizes the properties of plastics for better processing and quality.

Rubber: Increases strength and resistance in rubber products.

Paint: Acts as a filler to improve opacity and brightness.

Skimcoat and Coatings: Provides a smoother finish and consistency.

Water Treatment: Assists in pH adjustment and water softening.

Wall Panels, Ceramic, and Tile Adhesive: Improves structural integrity and usability.

Cost Between Coated and Uncoated Calcium Carbonate

The price of coated calcium carbonate tends to be higher than uncoated calcium carbonate due to the additional processing steps involved in the coating process.

These additional steps include surface treatment and the application of specialized coatings to enhance properties such as improved dispersibility, increased compatibility with other materials, and better performance in specific applications.

Despite the increased cost, coated calcium carbonate’s enhanced properties make it a suitable choice for applications where these properties are essential.

Discover more about our Coated and Uncoated Calcium Carbonate

Top reasons Vietnam’s CaCO3 Powder is exported to many Asian countries

Global Minerals 20 Years Journey Towards Global Success

Elevate Your Product Quality with Premium Coated Calcium Carbonate Powder from Global Minerals

Uncoated Calcium Carbonate Powder: Enhance Your Product Line

| Nhat Huy Group was established in 2004 as an exporter of calcium carbonate powder. Since then, it has developed as a Vietnamese manufacturer with excellent results in international markets. It focuses on calcium carbonate powder, plastic support materials, and quartz slabs. Nhat Huy has exported plastic and building stone materials to foreign countries, and the world is developing. |