Table of Contents

CaCO3 Powder for Filler Masterbatch has become a strategic material in the highly competitive plastics industry, where manufacturers face a constant dual challenge: optimizing production costs while consistently enhancing product quality.

More than just a filler, high-quality CaCO3 Powder forms the foundation for improving mechanical properties, streamlining production processes, and creating long-term competitive advantages for your business.

This comprehensive guide walks you through everything from foundational knowledge to in-depth technical analysis—helping you understand the role, selection criteria, and applications of CaCO3 Powder to produce outstanding filler masterbatch products.

Part 1: The Core Foundation – Why CaCO3 Powder for Filler Masterbatch Matters

CaCO3 Powder for Filler Masterbatch: The Unsung Hero of Filler Masterbatch

Behind every high-quality filler masterbatch pellet lies a key foundational ingredient—CaCO3 Powder for Filler Masterbatch. Its role goes far beyond simply “filling.” It is a functional component that helps:

- Reduce cost: By replacing a significant portion of costly virgin resins.

- Enhance mechanical properties: Improve rigidity, impact strength, and dimensional stability.

- Streamline production: Increase thermal conductivity, shorten cooling time, and boost output.

A Smart Choice: Exceptional Economic & Production Benefits

Compared to using 100% virgin resins, incorporating CaCO3 Powder into your masterbatch formula offers undeniable advantages:

- Economic benefit: CaCO3 Powder is far more affordable than PE, PP, or PVC resins, directly reducing material costs and increasing product competitiveness.

- Production benefit: With higher thermal conductivity than plastic resins, CaCO3 enables faster melting and cooling, leading to shorter production cycles and higher throughput.

The Journey of CaCO3 Powder: From Pure Limestone to Premium Quality

The quality of CaCO3 Powder for Filler Masterbatch starts at the quarry. Vietnam is blessed with some of the world’s purest and whitest limestone reserves. The journey to premium CaCO3 Powder includes:

- Mining & Selection: Carefully selected limestone blocks with >98.5% CaCO3 purity.

- Grinding & Classification: European grinding technology ensures ultra-fine particle size, while advanced classifiers guarantee uniformity.

- Surface Coating: Fatty acid (e.g., stearic acid) or functional coatings are applied to enhance resin compatibility and reduce equipment wear.

- QC & Packaging: Each batch undergoes strict quality checks before packing and delivery.

Part 2: Smart Selection – Key Technical Insights You Must Know

How to Choose the Right CaCO3 Powder for Your Masterbatch

Selecting the right CaCO3 Powder for Filler Masterbatch is critical. Focus on these four key parameters:

- Particle Size

- Ultra-fine (D97 < 10μm): Ideal for film applications requiring high gloss and tensile strength.

- Fine (D97 10–20μm): Suitable for injection molding and nonwoven applications.

- Standard (D97 > 20μm): Used for pipe and sheet extrusion where stiffness and cost-saving are key.

- Ultra-fine (D97 < 10μm): Ideal for film applications requiring high gloss and tensile strength.

- Whiteness: A higher whiteness (>98%) ensures better color matching and reduced pigment use.

- Moisture: Must be <0.2% to prevent bubble formation and defects during thermal processing.

- Purity: >98.5% CaCO3 content ensures chemical stability and compatibility with your additives.

CaCO3 Powder Quality Comparison: Vietnam’s Supply Advantage

On the global market, Vietnam, India, and Egypt are among the most common sources of CaCO3 Powder. However, they differ significantly in key quality aspects:

| Criteria | Vietnam | India | Egypt |

| Purity | Very high (>98.5%) | Moderate, may contain more impurities | High |

| Whiteness | Outstanding (>98%) | Medium to good | Very good |

| Consistency | Very high – supported by modern tech | Varies by manufacturer | Good |

| Main Advantage | Premium quality, competitive pricing, strategic location in Asia | Low cost | Good quality |

Conclusion: Vietnamese CaCO3 Powder stands out as the most well-balanced choice in terms of purity, brightness, and cost-efficiency.

Explore our milestone: The Most White And Bright Calcium Carbonate Power Source In The World From Global Minerals

The Quality Keys: Dispersion and Color Stability

Low-quality or poorly coated CaCO3 Powder can cause clogging and pressure spikes in extrusion lines. In contrast, premium coated CaCO3 Powder ensures:

- Excellent dispersion: Uniform mixing in polymer matrix for consistent masterbatch.

- Color stability: High whiteness and even coating prevent shade variation and build customer trust.

Real-World Applications: Film, Injection & Extrusion Masterbatch

- Film (Blown): Ultra-fine CaCO3 Powder (D97 = 5–8μm) ensures excellent dispersion and tear resistance.

- Injection Molding: Requires fine, well-dispersed powder for high rigidity and low shrinkage.

- Extrusion: Coarser CaCO3 Powder helps reduce cost, increase stiffness, and maintain shape stability.

Part 3: Trusted Partnerships – Building Confidence and Driving Success

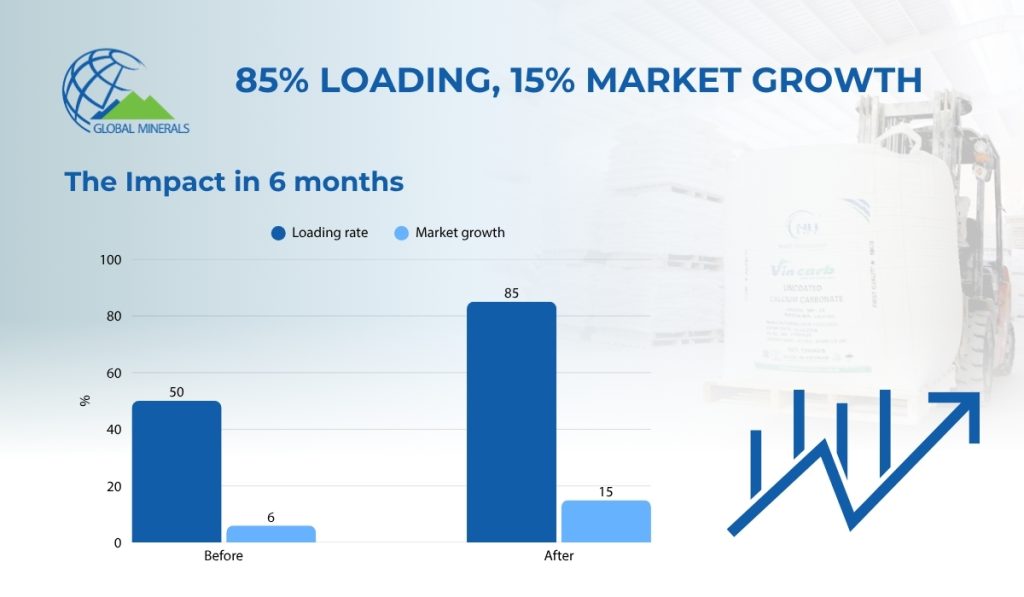

Case Study: 85% Loading, 15% Market Growth

A Chinese masterbatch producer struggled to raise CaCO3 Powder loading beyond 82% due to agglomeration and breakage issues. Their previous supplier’s inconsistent quality led to production instability and customer complaints.

Our Solution: With technical consultation and trials, they switched to our ultra-fine (D97 = 5μm), narrow PSD, surface-coated CaCO3 Powder.

Results:

- New product success: Achieved 85% loading, launching a premium-grade filler masterbatch.

- Production boost: 30% reduction in downtime due to smoother twin-screw extrusion.

- Fewer complaints: Improved dispersion eliminated agglomerates and customer issues.

- Market growth: 15% market share gain within 6 months.

Golden Commitment: A Quality Control Process That Guarantees Consistency

Trust is built on consistency. Our multi-layered QC system includes:

- Advanced Lab Testing: Particle Size Distribution (Malvern, UK), Whiteness (Konica Minolta, Japan), moisture content, purity, and OAN are measured on every batch.

- COA Documentation: A Certificate of Analysis is issued per lot—guaranteeing your specifications.

Beyond Supplier: A Long-Term Strategic Partner

We don’t just sell a product—we offer a complete solution:

- Technical Consultation: Tailored CaCO3 Powder selection for your specific application.

- Custom Formulations: We co-develop your unique masterbatch formula.

- Ongoing Support: Collaborating with you to solve challenges and drive sustainable growth.

Part 4: Advanced Knowledge – Leading the Market

The Critical Role of Particle Size Distribution (PSD) in CaCO3 Powder for Filler Masterbatch

Beyond D50, a narrow PSD (uniform particle sizes) offers clear advantages:

- Better dispersion

- More consistent mechanical performance

- Smoother surface finish on end products

What Is the Optimal CaCO3 Powder Loading Rate?

There’s no one-size-fits-all answer—it depends on:

- Application: Films (10–30%), pipe extrusion (up to 60%).

- CaCO3 Powder quality: Higher purity and better coating allow higher loading without quality compromise.

- End-use requirement: Premium masterbatch may limit filler usage to maintain strength.

Decoding Oil Absorption Number (OAN)

OAN measures the oil absorbed per 100g of CaCO3 Powder. Lower OAN is better:

- Requires less resin and additives for wetting

- Enhances flowability

- Cuts additive costs and improves efficiency

CaCO3 Powder and the Future of Sustainable Plastics

CaCO3 Powder plays a critical role in sustainability:

- Reduces virgin plastic use: Less dependence on fossil-fuel-based resins.

- Lowers carbon footprint: CaCO3 Powder processing consumes less energy than polymer production.

Ready to Upgrade Your Filler Masterbatch?

CaCO3 Powder is no longer optional—it’s strategic. The right product and supplier will reshape your cost, quality, and efficiency outcomes.

Let’s elevate your masterbatch performance together. Contact our expert team for free samples, technical consultation, and competitive quotations.

[📩 REQUEST TECHNICAL CONSULTATION]